Cutting Tools Division

We design and manufacture cutting tools for various sectors, including aviation, architecture, manufacturing, pipeline, defense, robotics, technology, and industrial applications.

Carbide Cutting Tools

We specialize in a wide range of carbide cutting tools, including:

- Carbide end mills

- Carbide ball nose and micro cutters

- Carbide drill bits and step drills

- Carbide reamers

- Single and double end Chamfer cutters

- Form cutters

- Countersinks

- Profile milling cutters as per requirements

- Single lip cutters

- Radius cutters

- T slot mills and grooving cutters

- Centre drills

- Pilot drills and reamers

- Dove tail cutters

- Counter boring tools

- Custom and special drills

- Flaring tools and form tools

- Special pins

- ID tools

- Shearing blades and stencils

- Customized tools

- Wood roughing cutters

- Parting tool

- Regrinding Spot face cutters and lancer drill bits

- Regrinding of inserts and taps

- Regrinding of core cutters

- Regrinding of twist drills and beveling tools

- Shearing blades and stencils

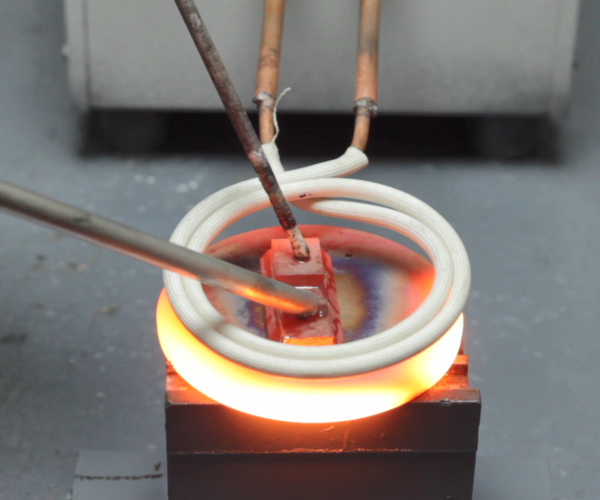

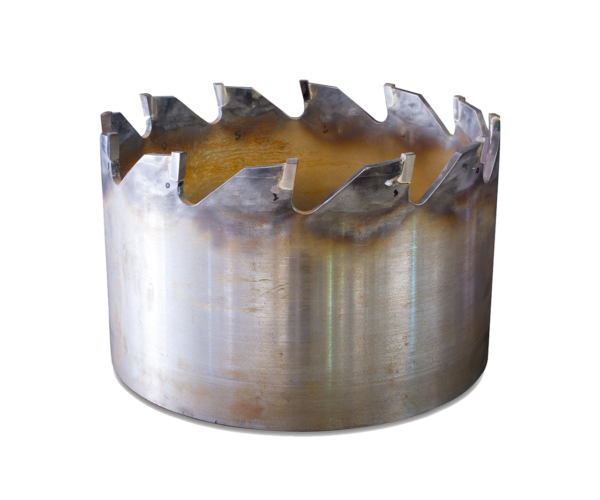

Brazed Or Tipped Tools

We design and manufacture various brazed tools as per customer requirements, including:

- Hot tapping cutters and pilot drills

- Concrete cutting blades

- Special drills

- Brazed reamers

- Special cutters

- Spline cutters

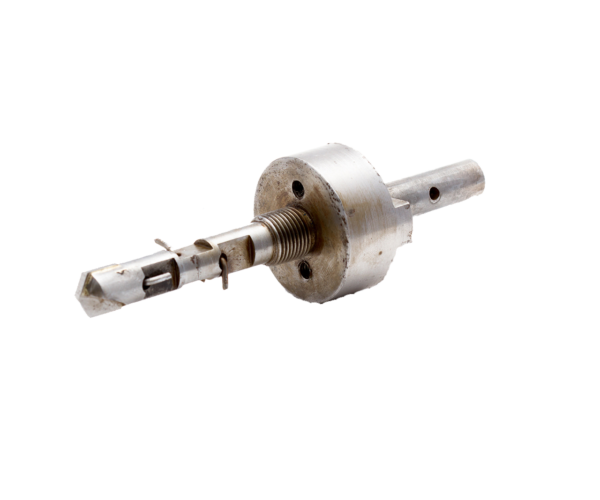

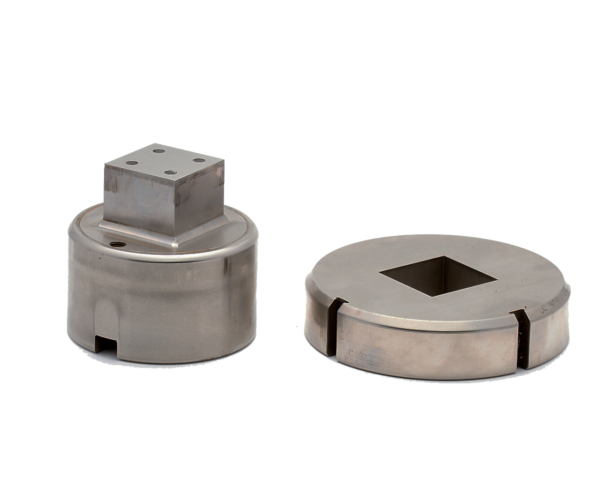

Tools That Require Fabrication & Machining

We offer tools requiring fabrication and machining, such as:

- Hot tapping cutters and pilot drills

- Special tools and tool holders

- Washers, pins and sockets

- Gauges and punches

- Wear pads and tools

- Shafts

For Manufacturing & Repair

Shaheen can re-engineer replacements for small and large cutting tools. These parts can be reverse-engineered or modified for improved performance characteristics based on client requirements.

Additional Products and Services

We also provide:

- Induction brazing tools

- Custom carbide drills

- Services from leading carbide cutting tools manufacturers and cutting tools manufacturers

- Industrial cutting tools for various applications

Quality Control

ISO 9001:2015

Quality is never an accident; it is always the result of high intention, sincere effort, intelligent direction and skillful execution; it represents the wise choice of many alternatives.” – William A

LEAVE US YOUR INFO

and we will get back to you.