Our Company

‘WE ARE COMMITTED TO PROVIDING OUR CUSTOMERS WITH PRODUCTS AND SERVICES THAT CONTINUALLY MEET OR EXCEED THEIR EXPECTATIONS’

Rotating Equipment Division

SHAHEEN currently offers services in:

-precision fabrication & machining,

-reverse engineering, and

-repair & manufacture of rotating equipment components.

SPECIALISTS

In the manufacture and repair of rotating equipment components like the full range of hydro dynamic bearings, oil & air seals, hydrogen seals, deflectors, and oil baffles to name a few. We are capable of manufacturing non-standard parts as per customer requirements for generators, turbines, motors, pumps, compressors and gearboxes. We can also supply all kinds of spares required for gas and steam turbine maintenance.

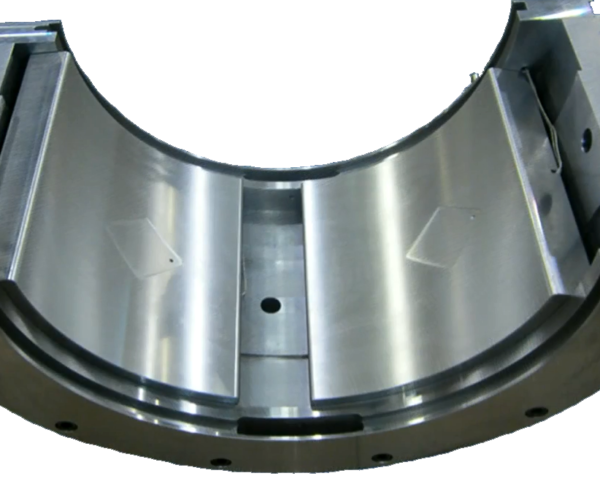

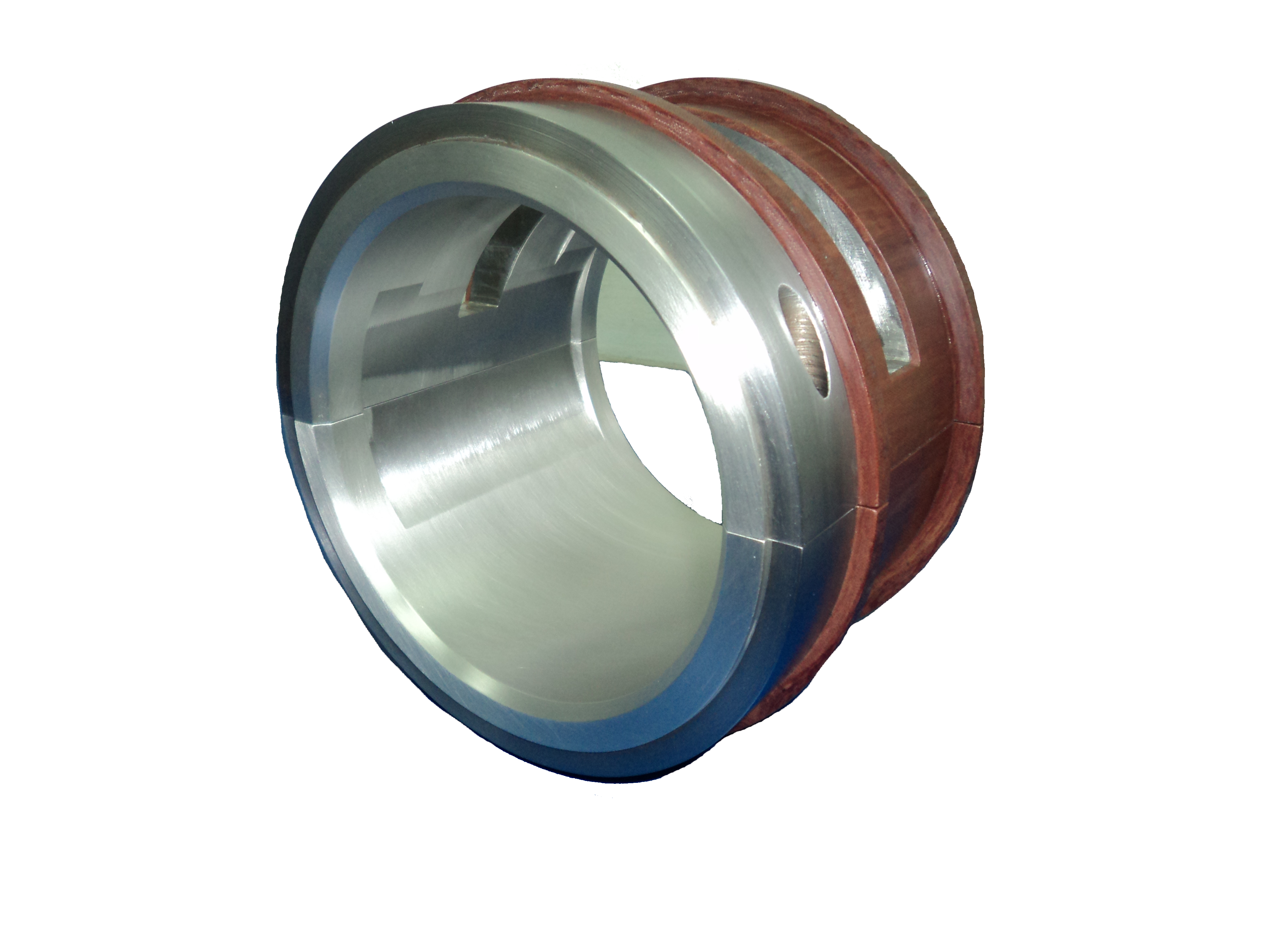

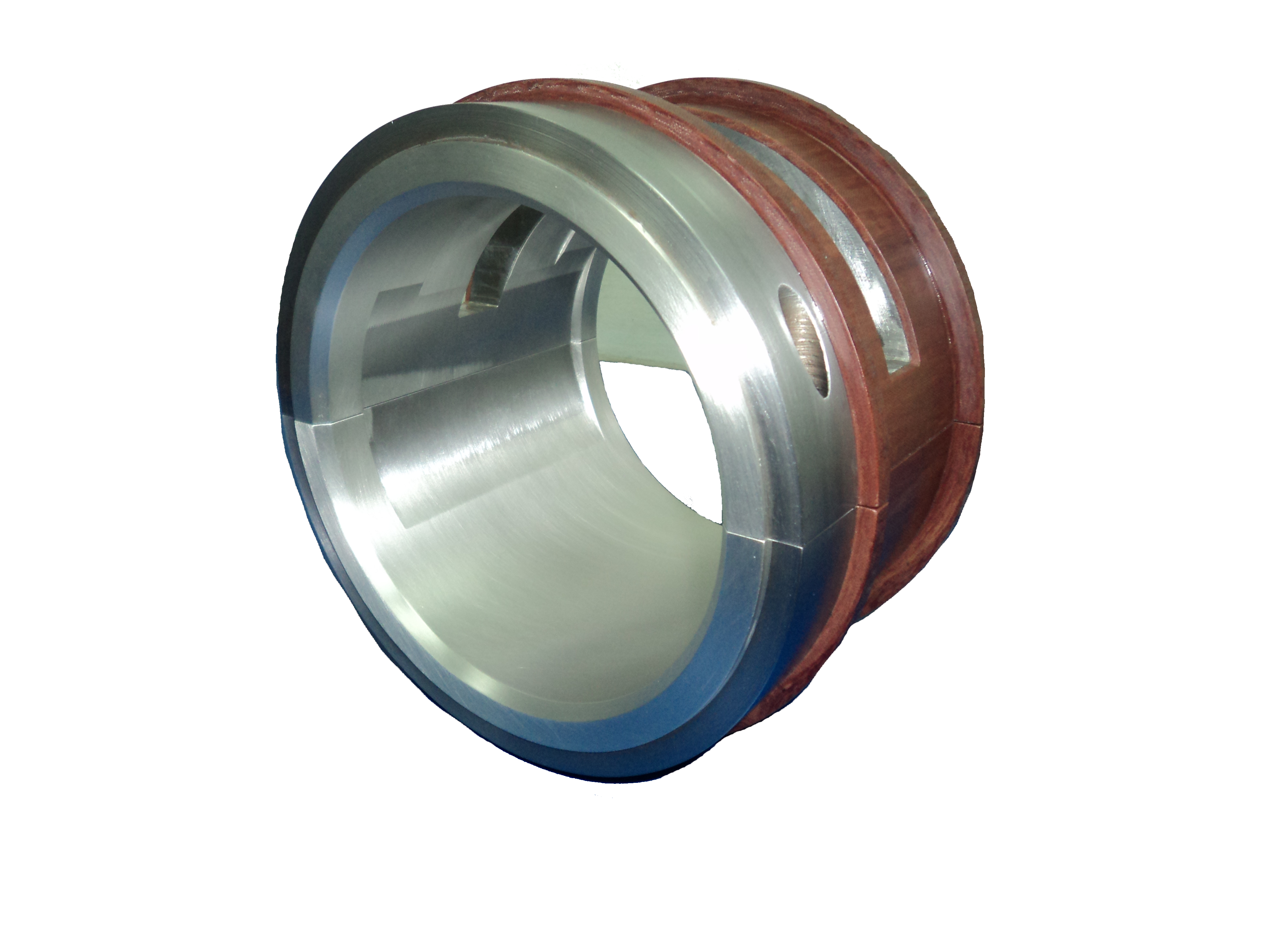

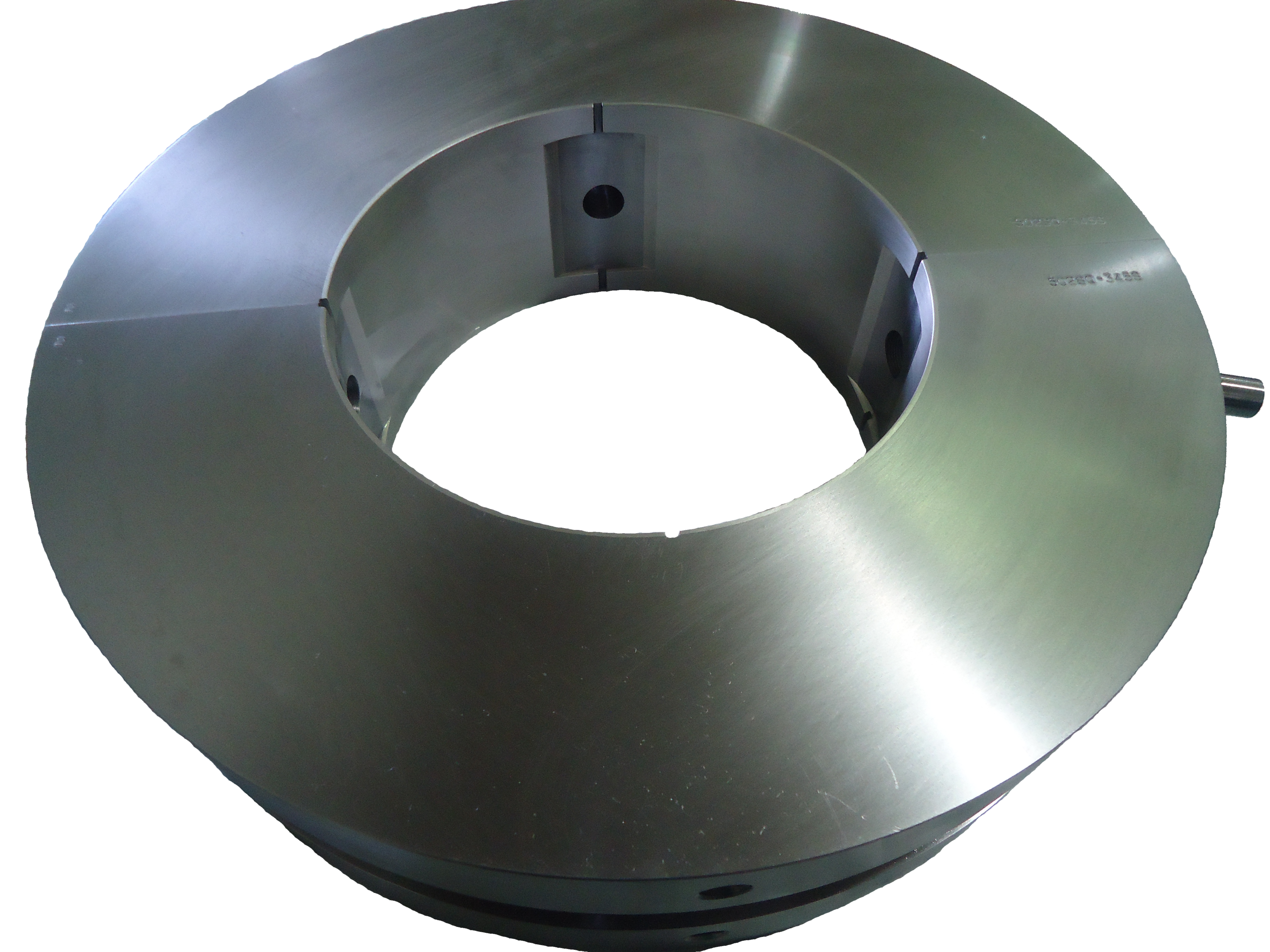

BEARINGS

MANUFACTURE & REPAIR

There are three key requirements in manufacturing a reliable bearing system:

-capability in metallurgical casting technology,

-knowledge of tribology and metal systems, and

-the ability to control hydrodynamic oil films.

WHITE METAL PROCESSES

Centrifugal casting is recognized as the best technique to line bearings with white metal. This is aided by ensuring a thorough bonding process by fully inserting the bearing in pure tin before the casting process. Depending on the type, all bearings are manufactured and repaired using centrifugal casting with our very own spin casting machine.

ROTATING EQUIPMENTS

MANUFACTURE & REPAIR

SHAHEEN provides services to both – End users and Original Rotating Equipment Manufacturers

CAPABILITIES

We can manufacture and repair a wide variety of components and parts for:

-Turbines,

-Gearboxes,

-Generators,

-Fans,

-Motors,

-Compressors,

-Pumps, and

-Diesel Engines.

COMPONENTS WE EXCEL AT

An example of the components we can deliver are:

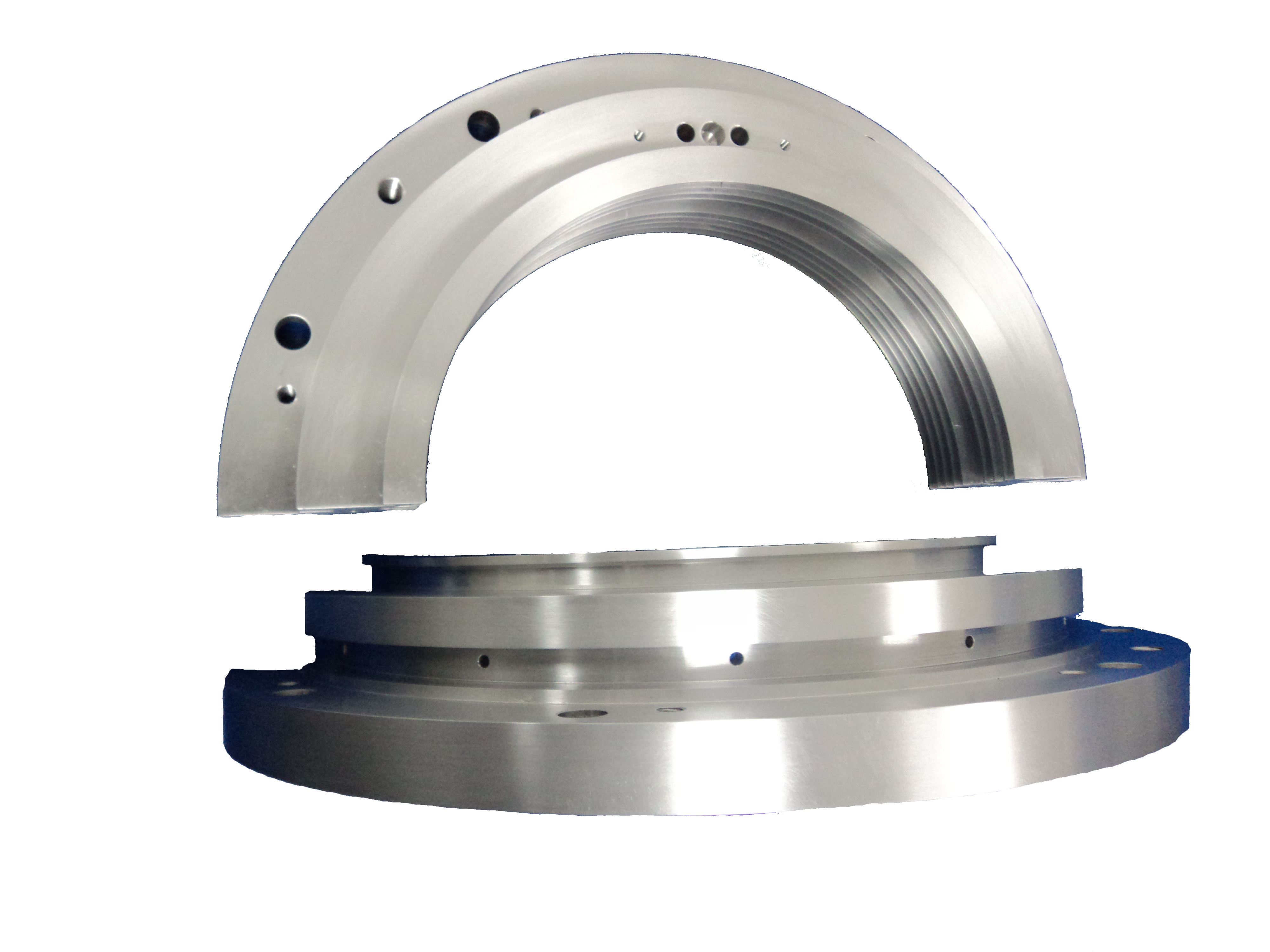

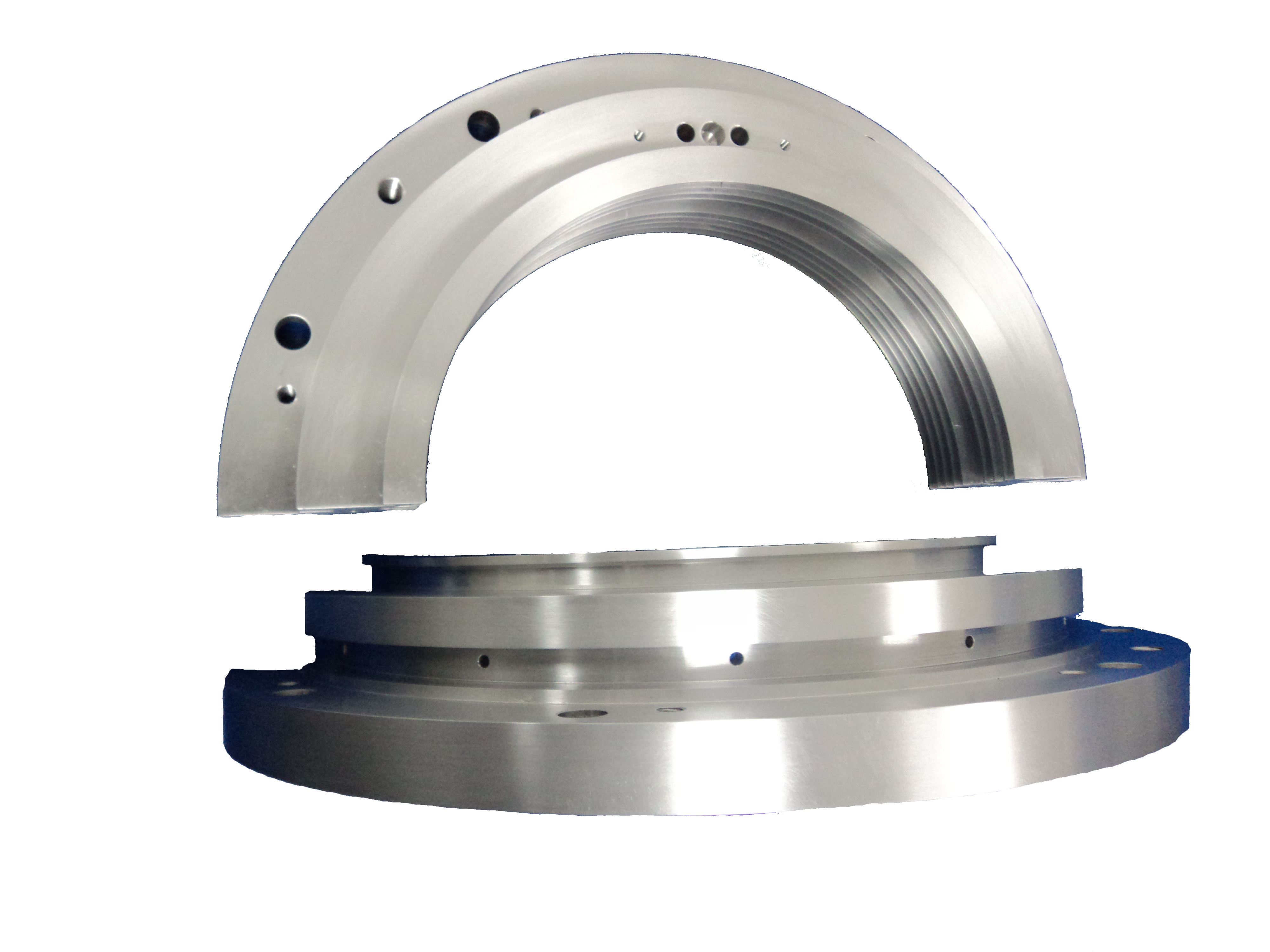

– Journal bearings (Sleeve)

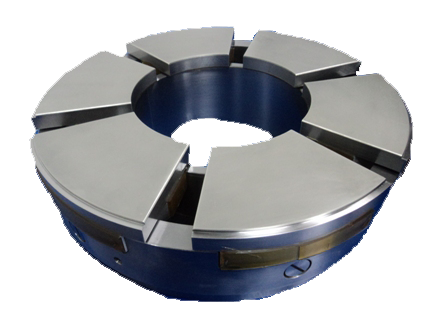

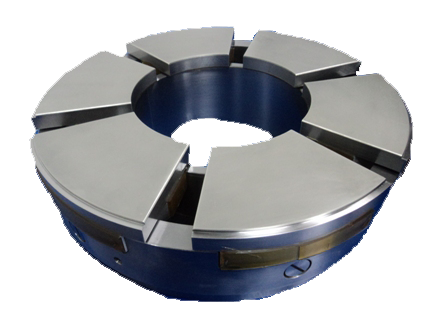

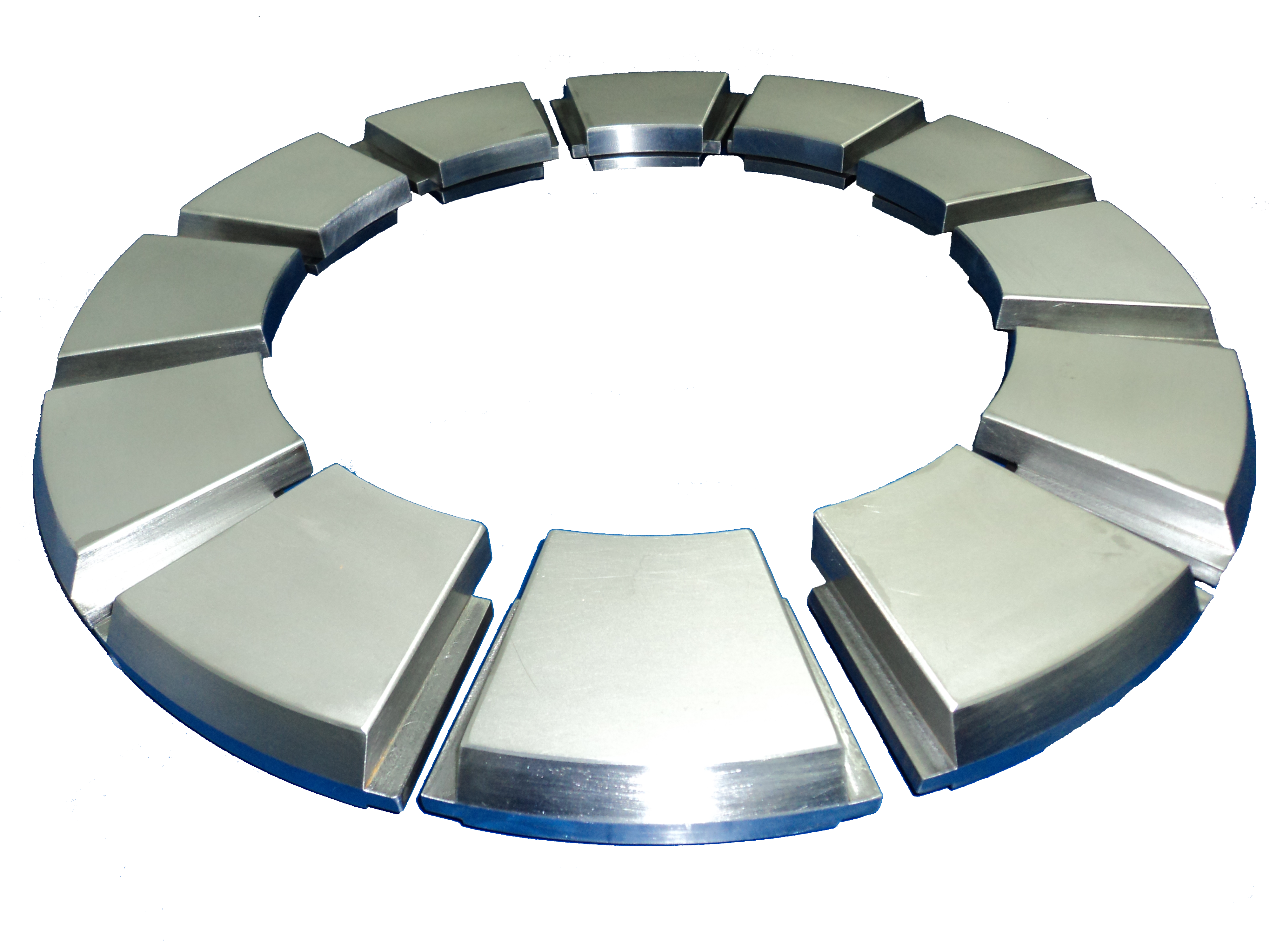

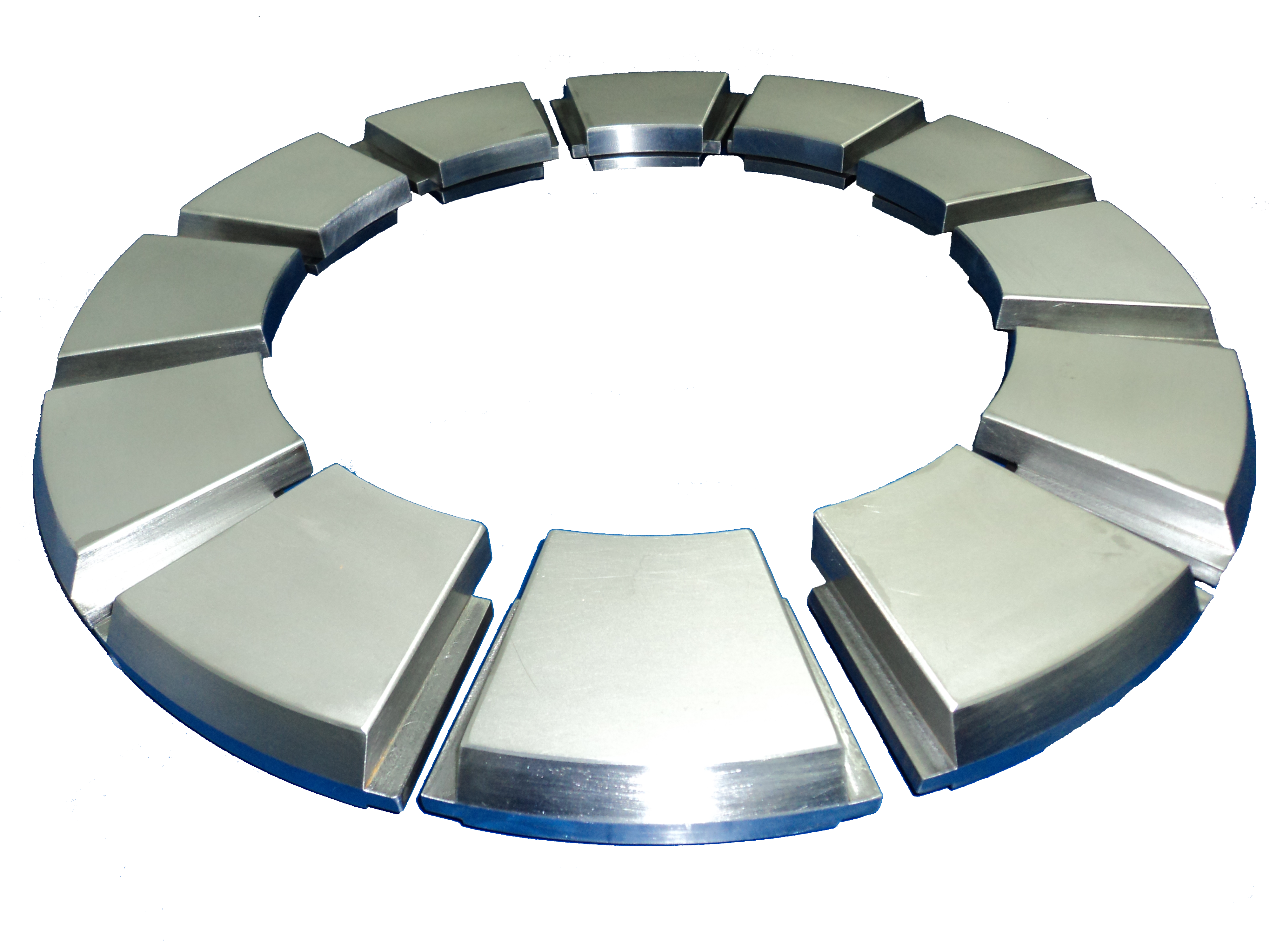

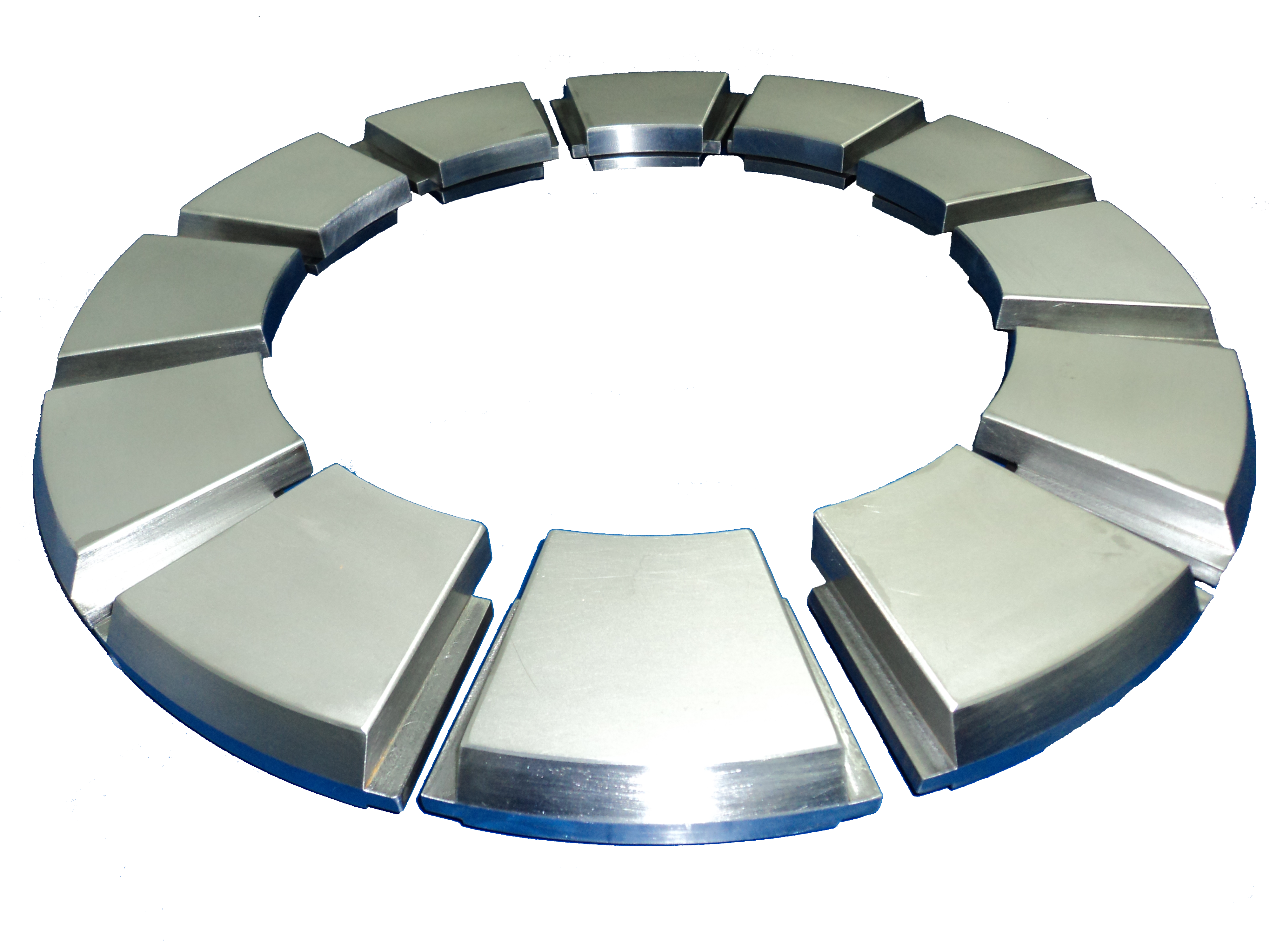

– Thrust bearings,

– Combined Journal & Thrust Bearings,

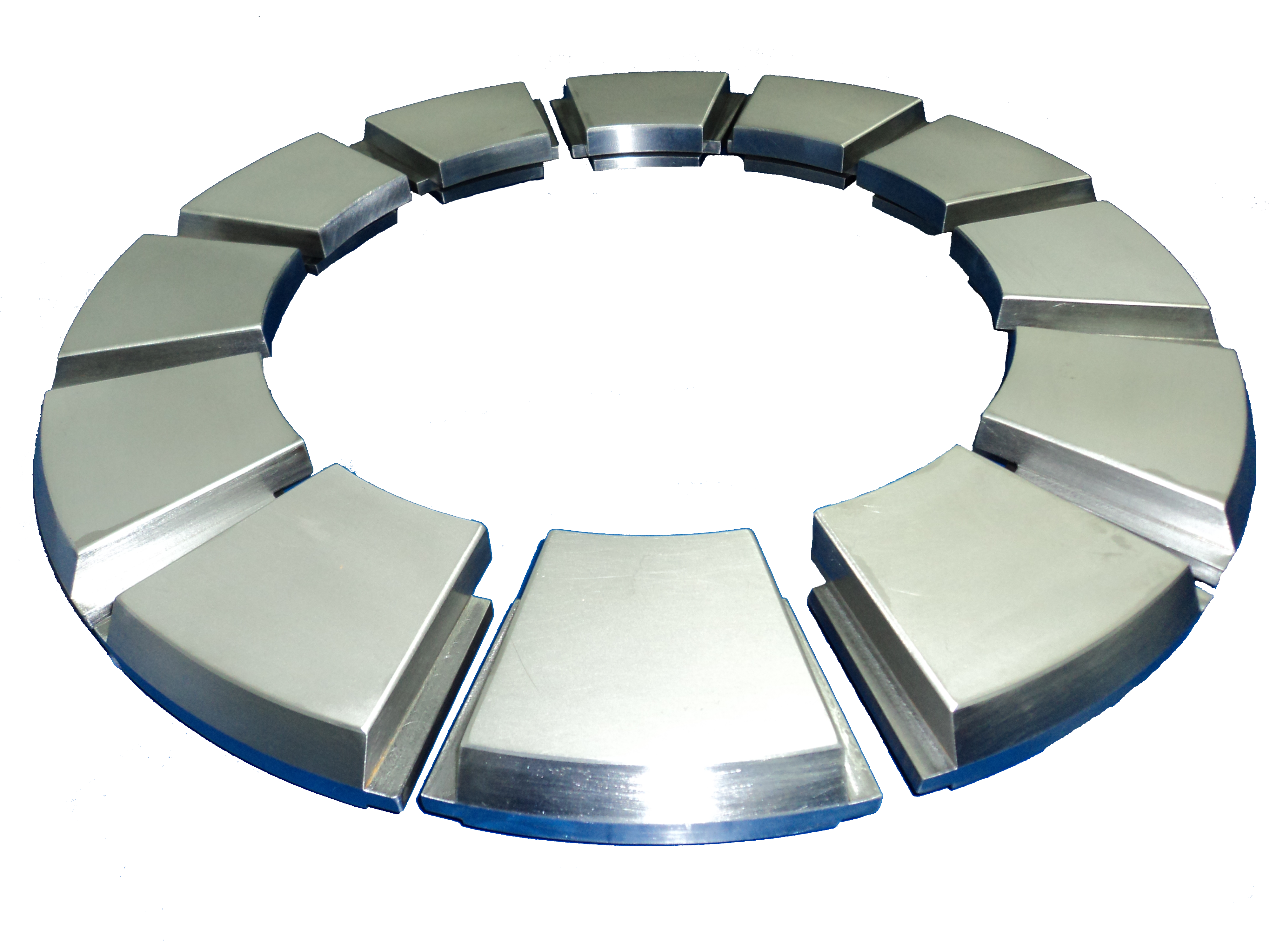

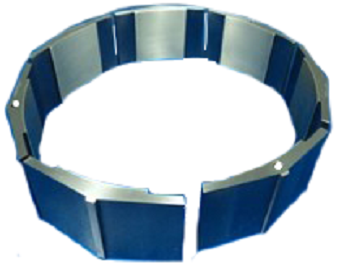

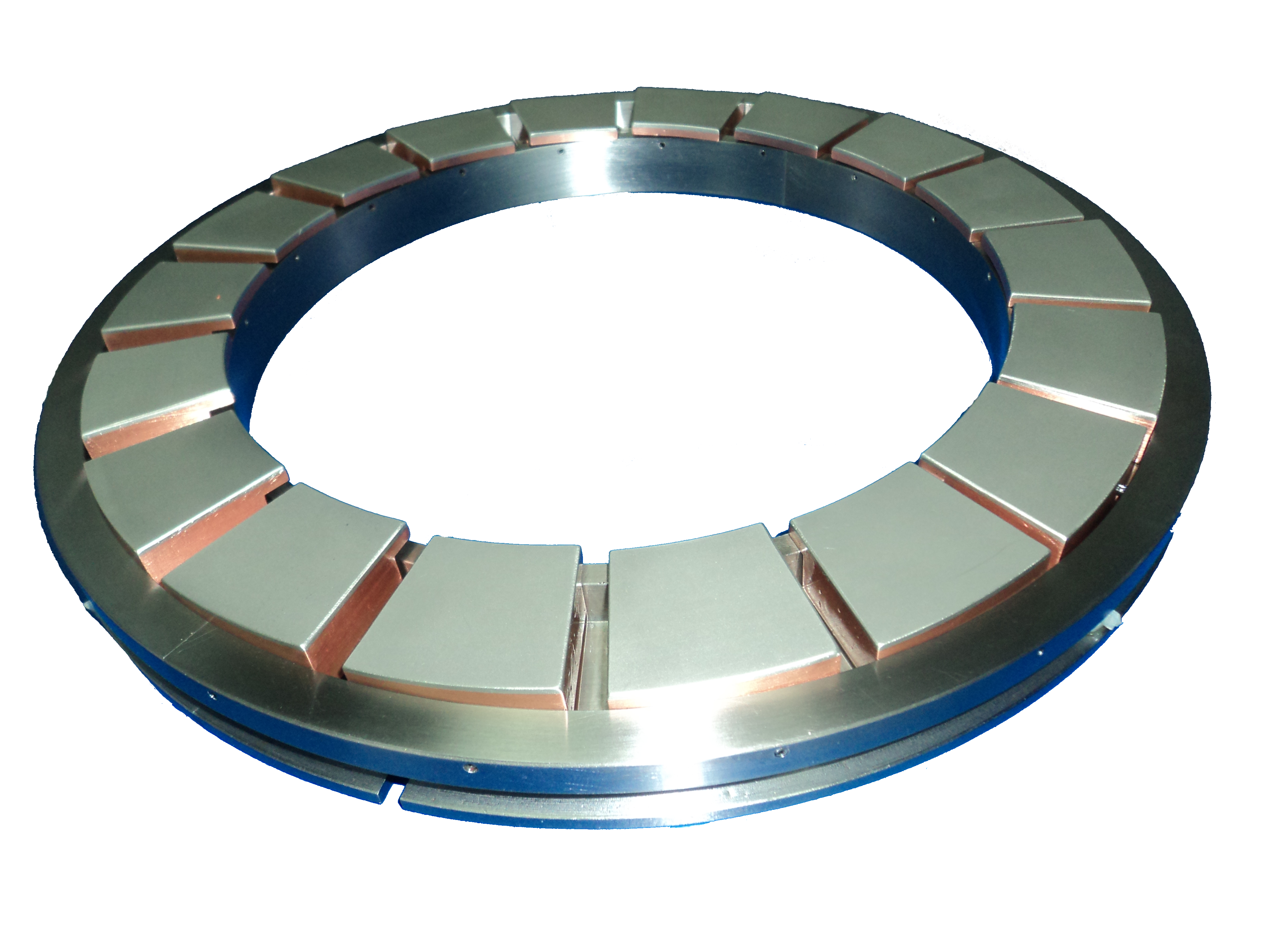

– Thrust Pads,

– Journal Pads,

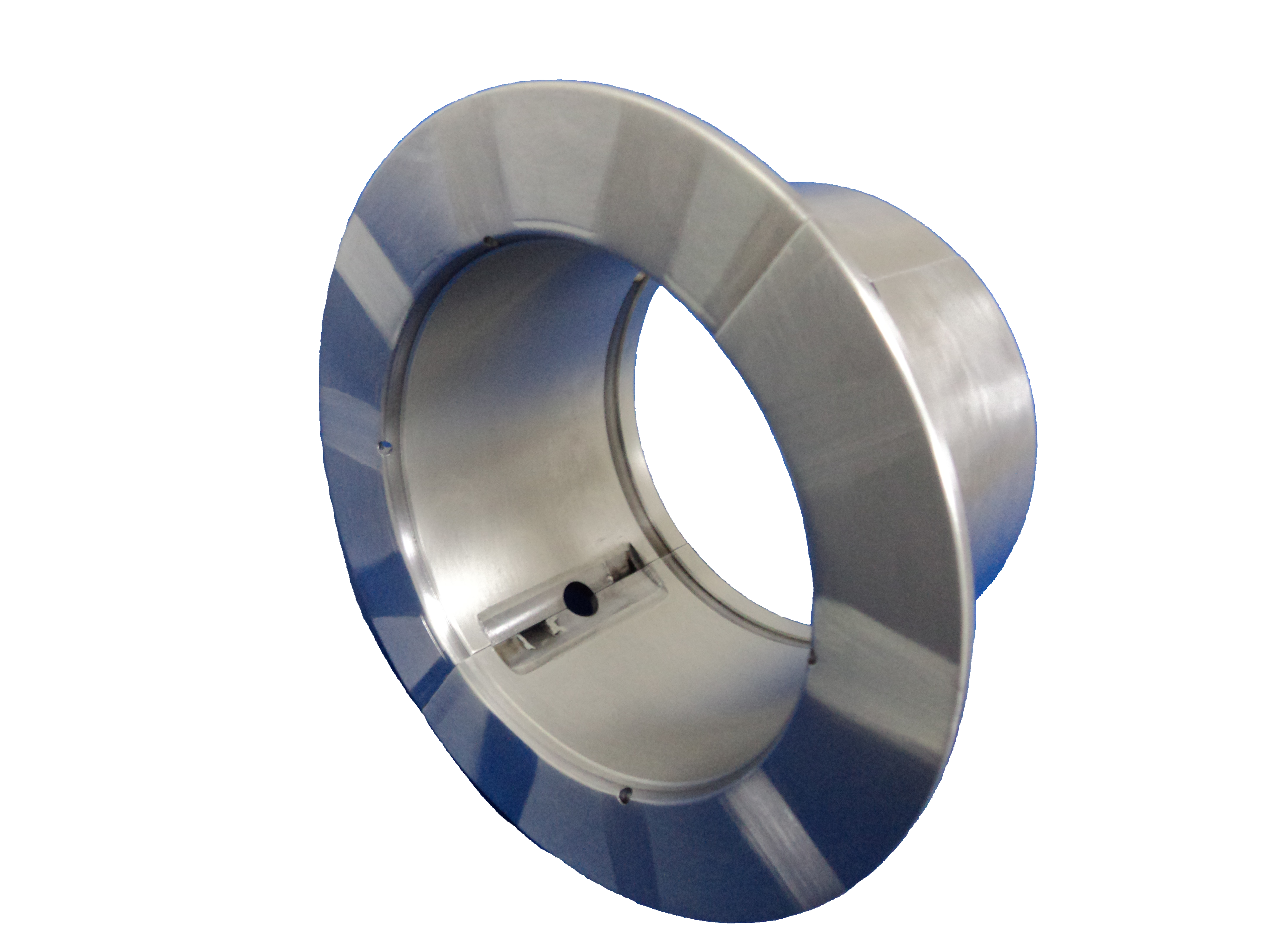

– Generator end Caps,

– Oil Deflectors,

– Crosshead Slides,

– Hydrogen Seals,

– Seal Rings, and

– Oil Seals to Name a few.

MANUFACTURED COMPONENTS

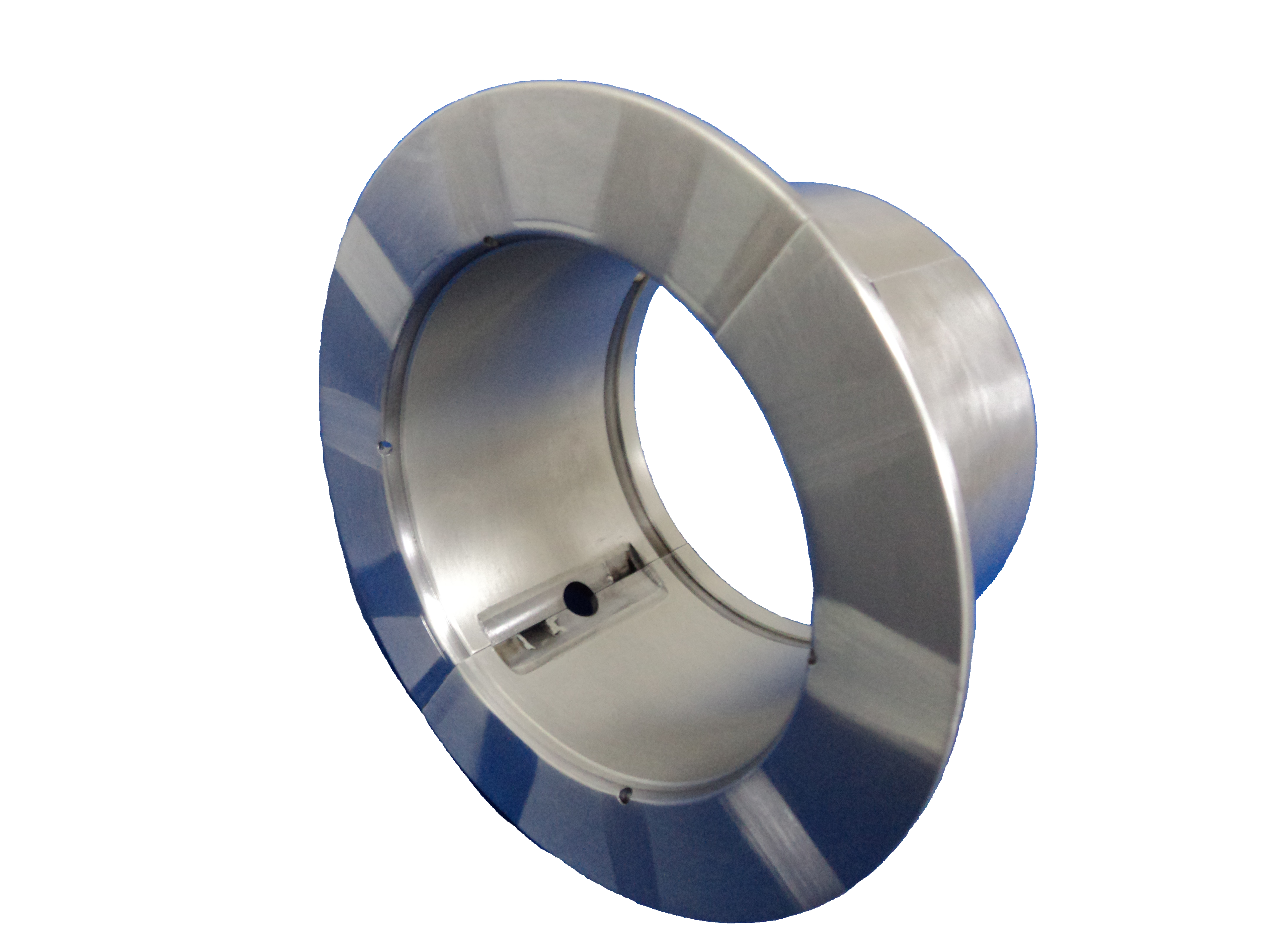

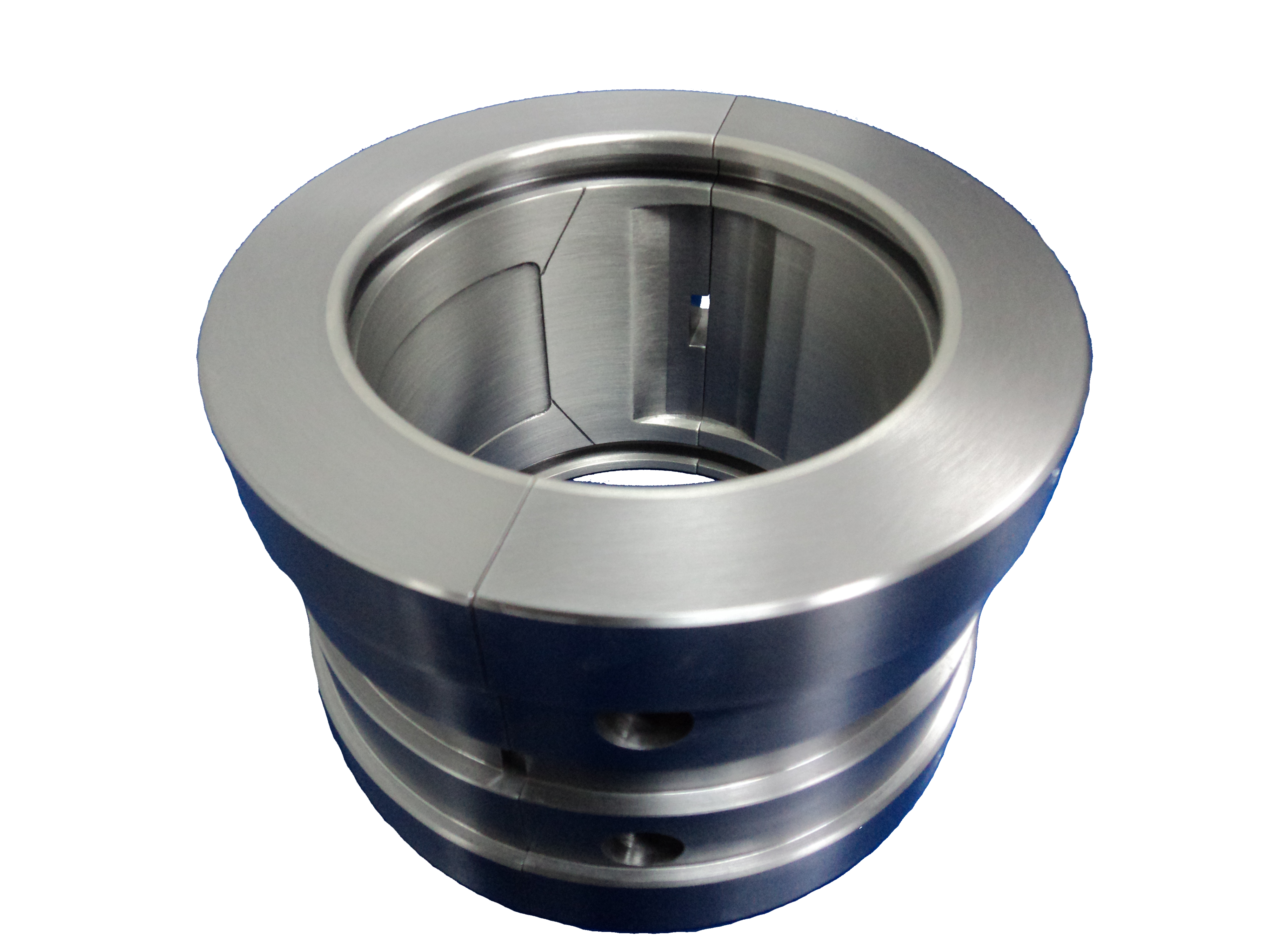

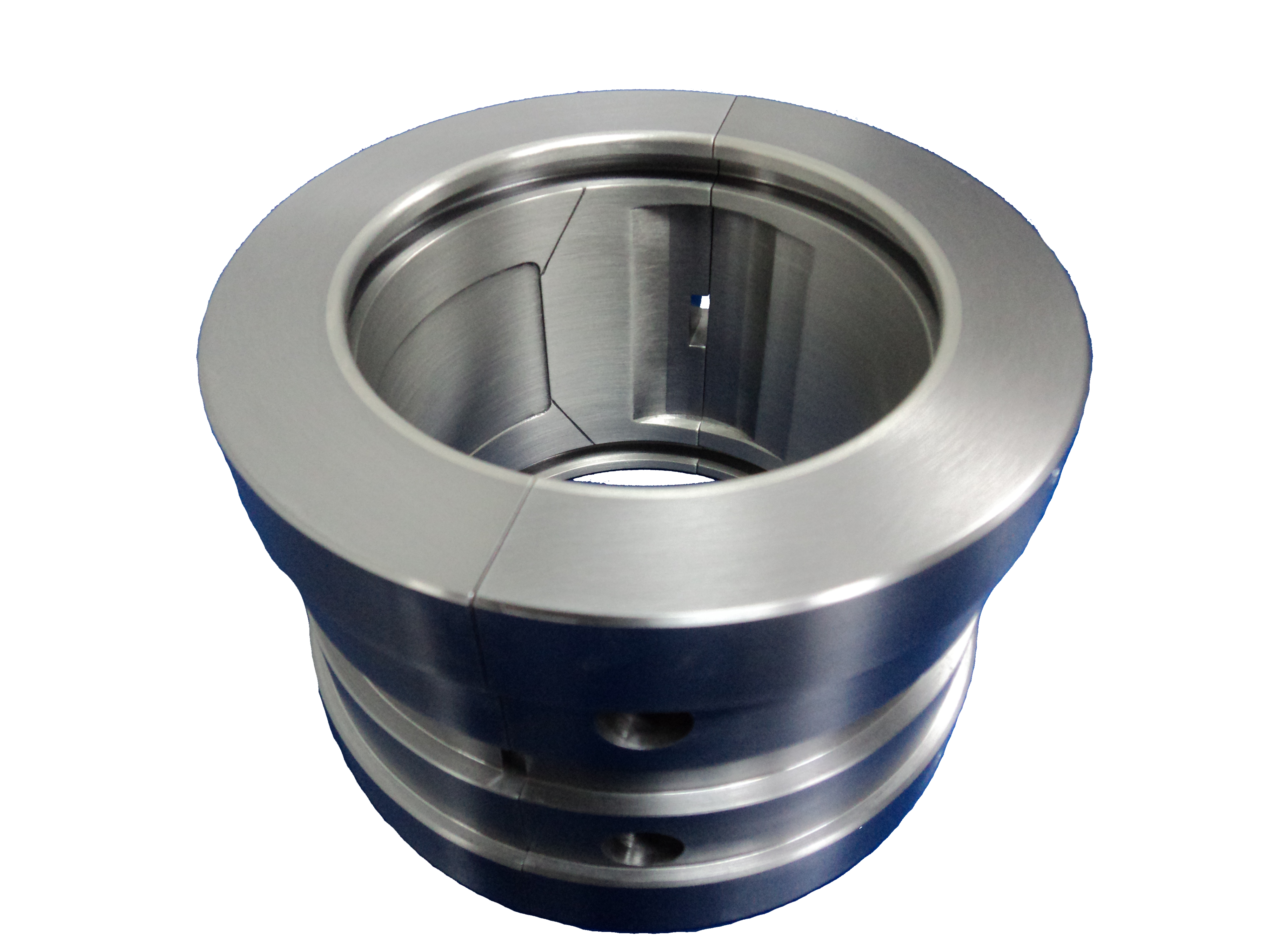

HS Seals for Gear Boxes

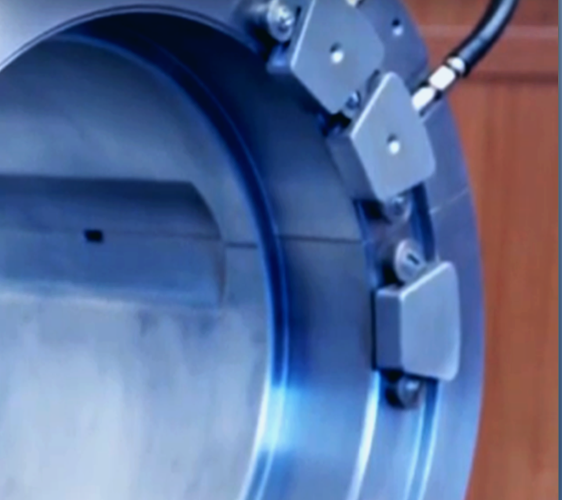

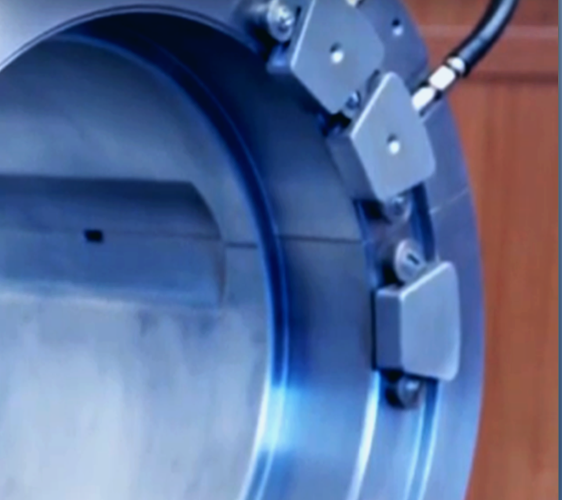

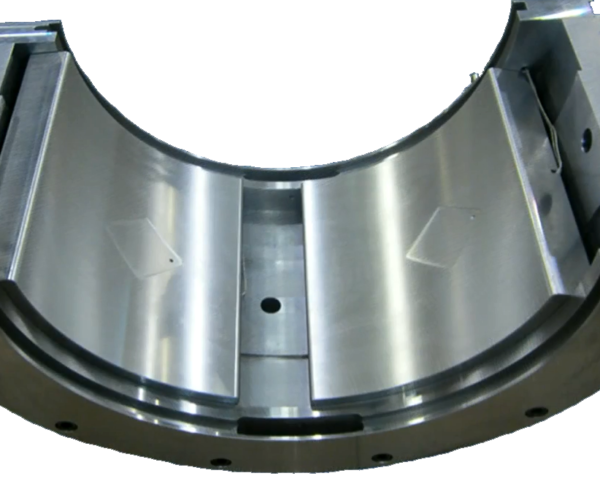

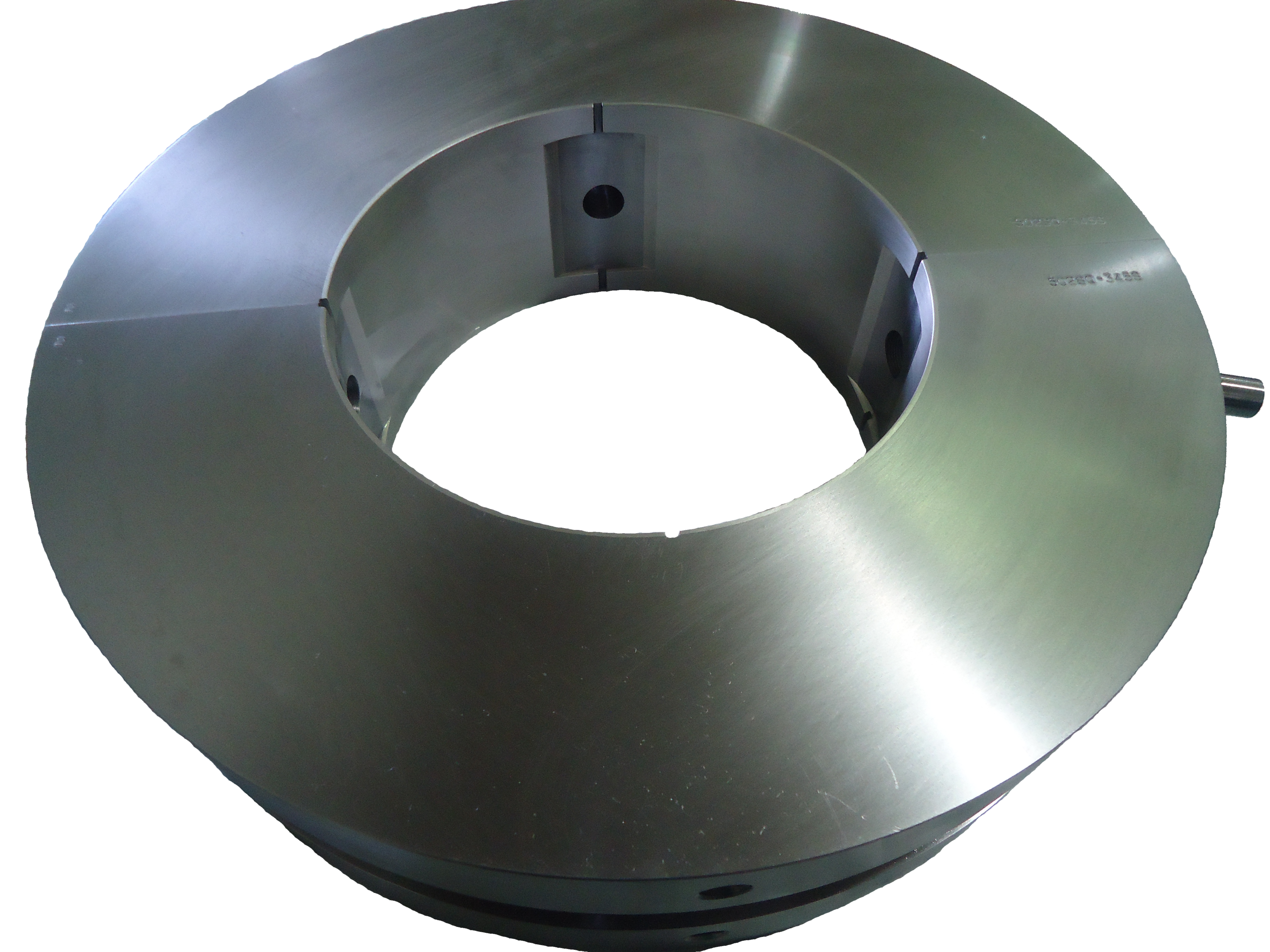

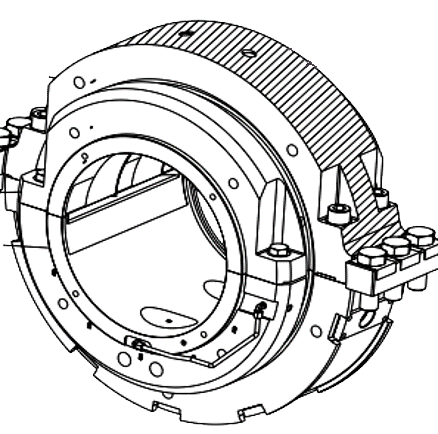

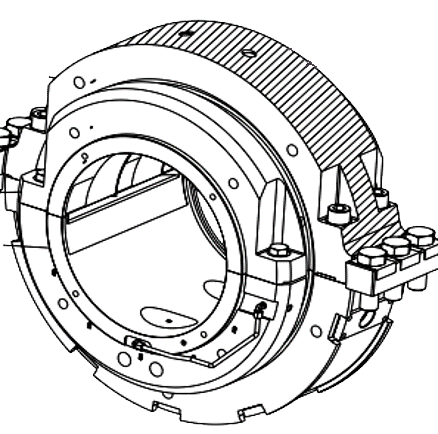

Pad Seated Bearings with End Seals

Motor Bearings

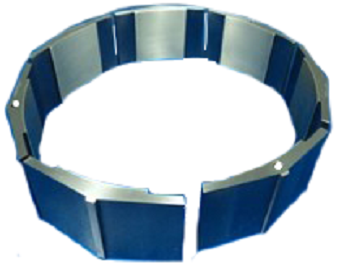

Floating Seals

Journal Pads for Vertical Bearings

Pressure Dam Bearings

Tilting Pad Journal Bearings

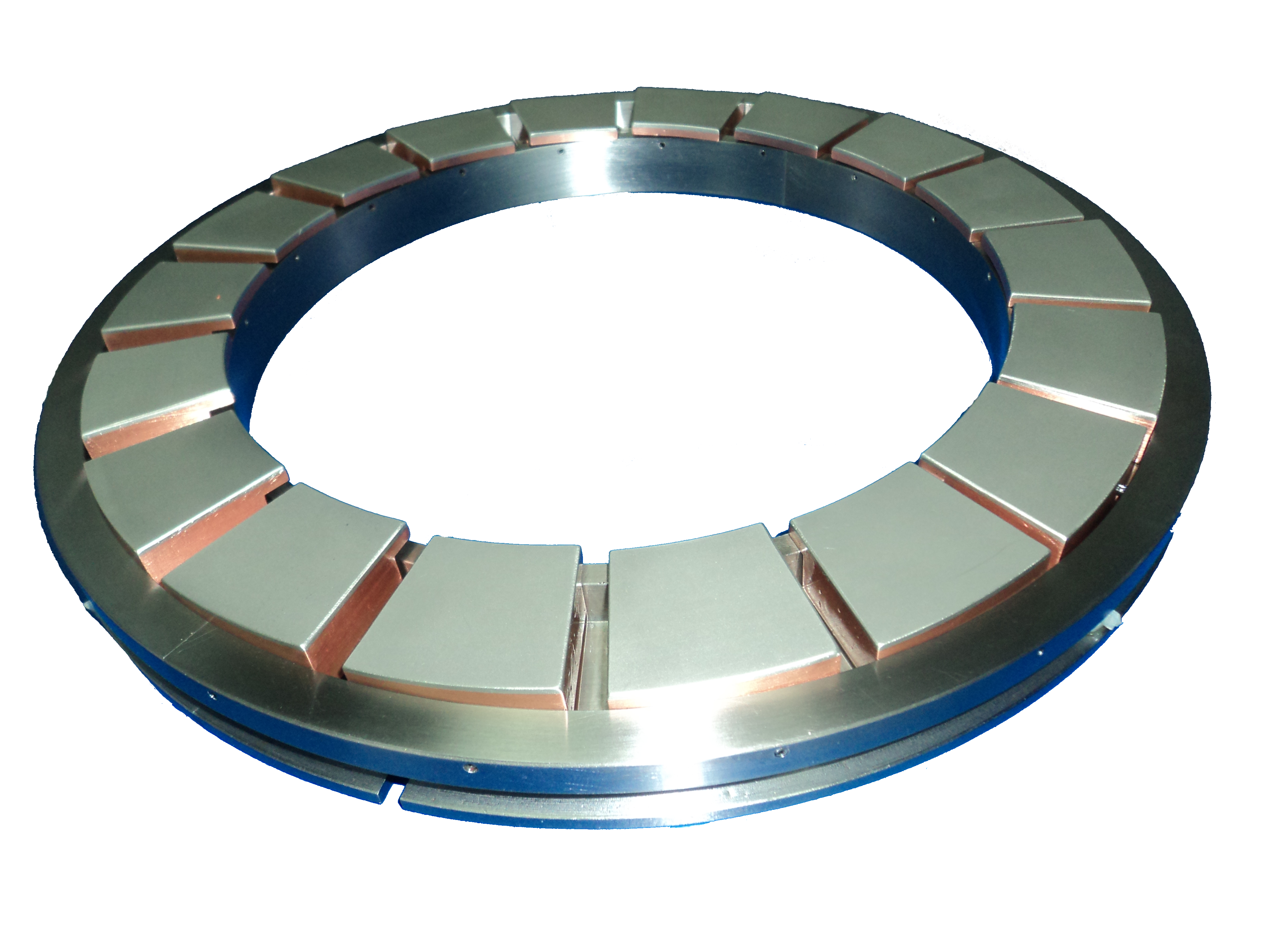

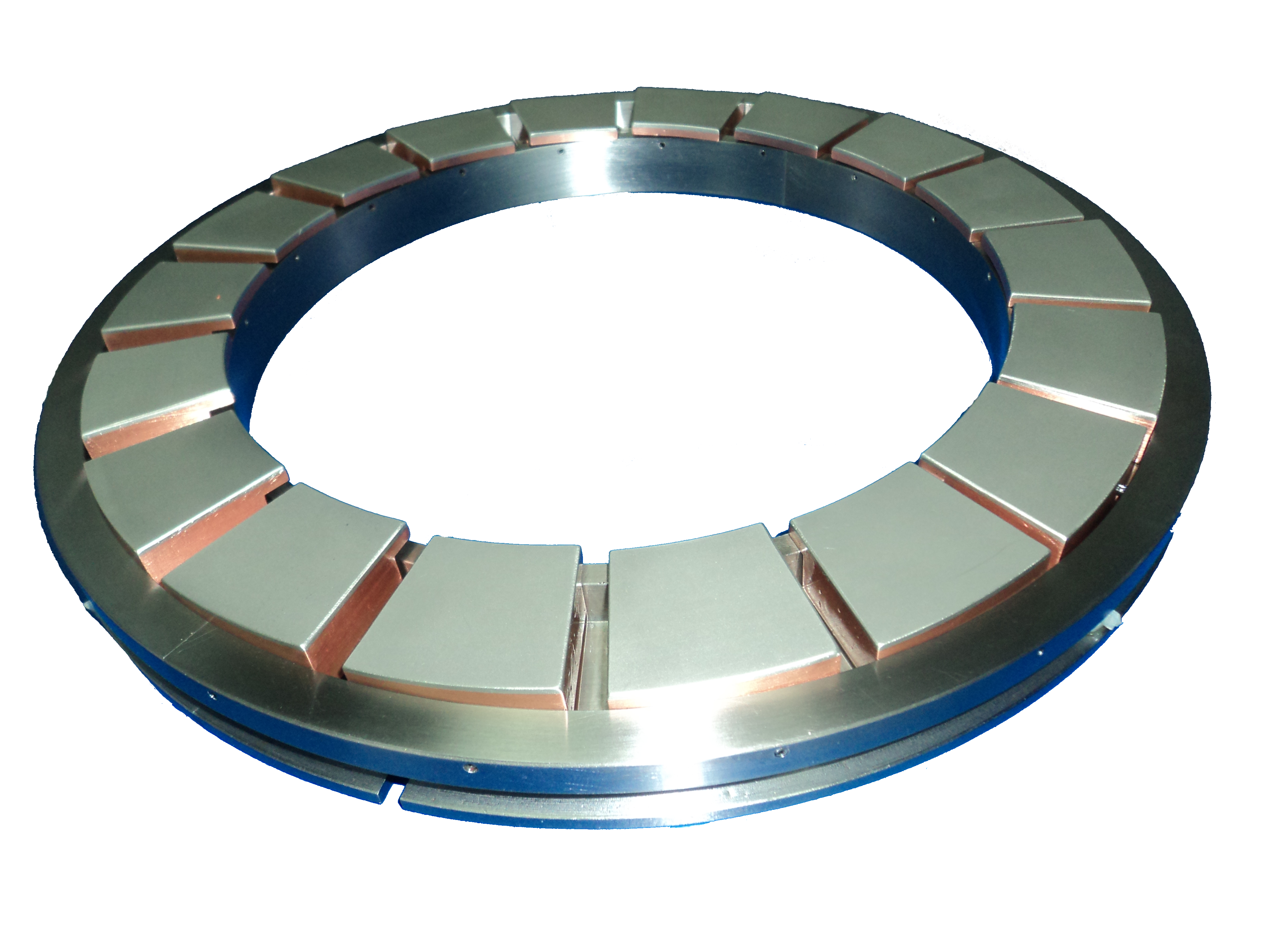

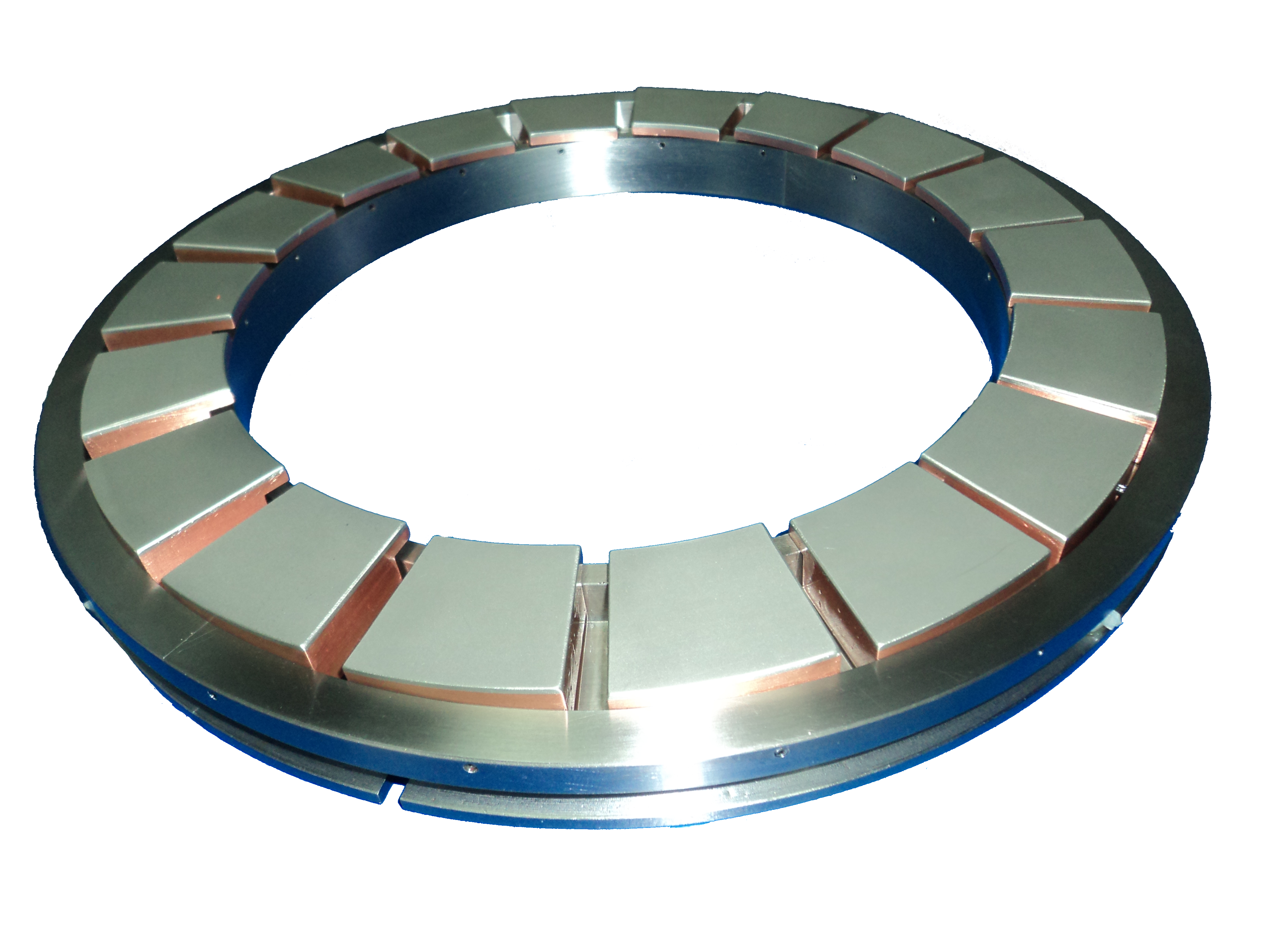

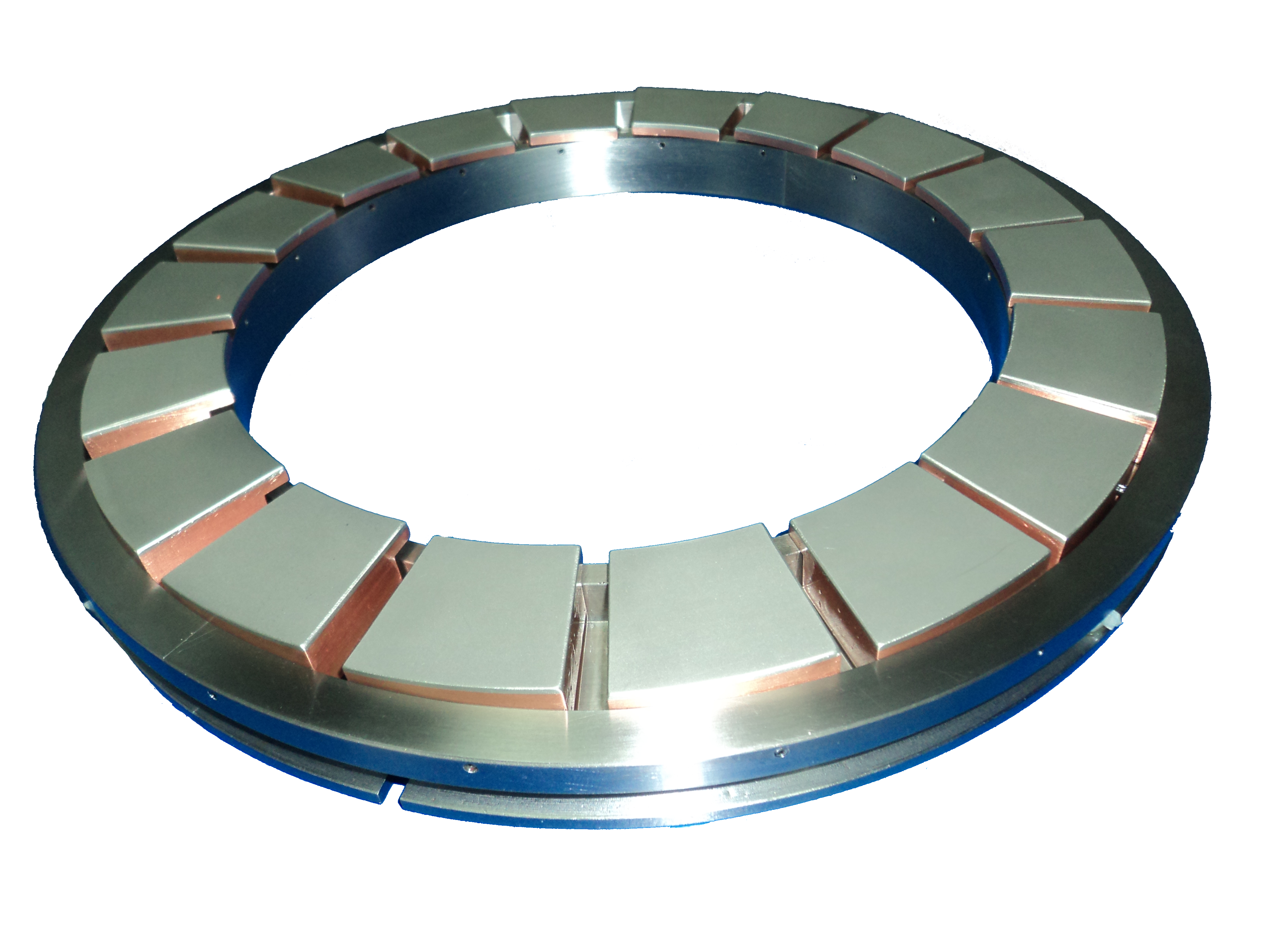

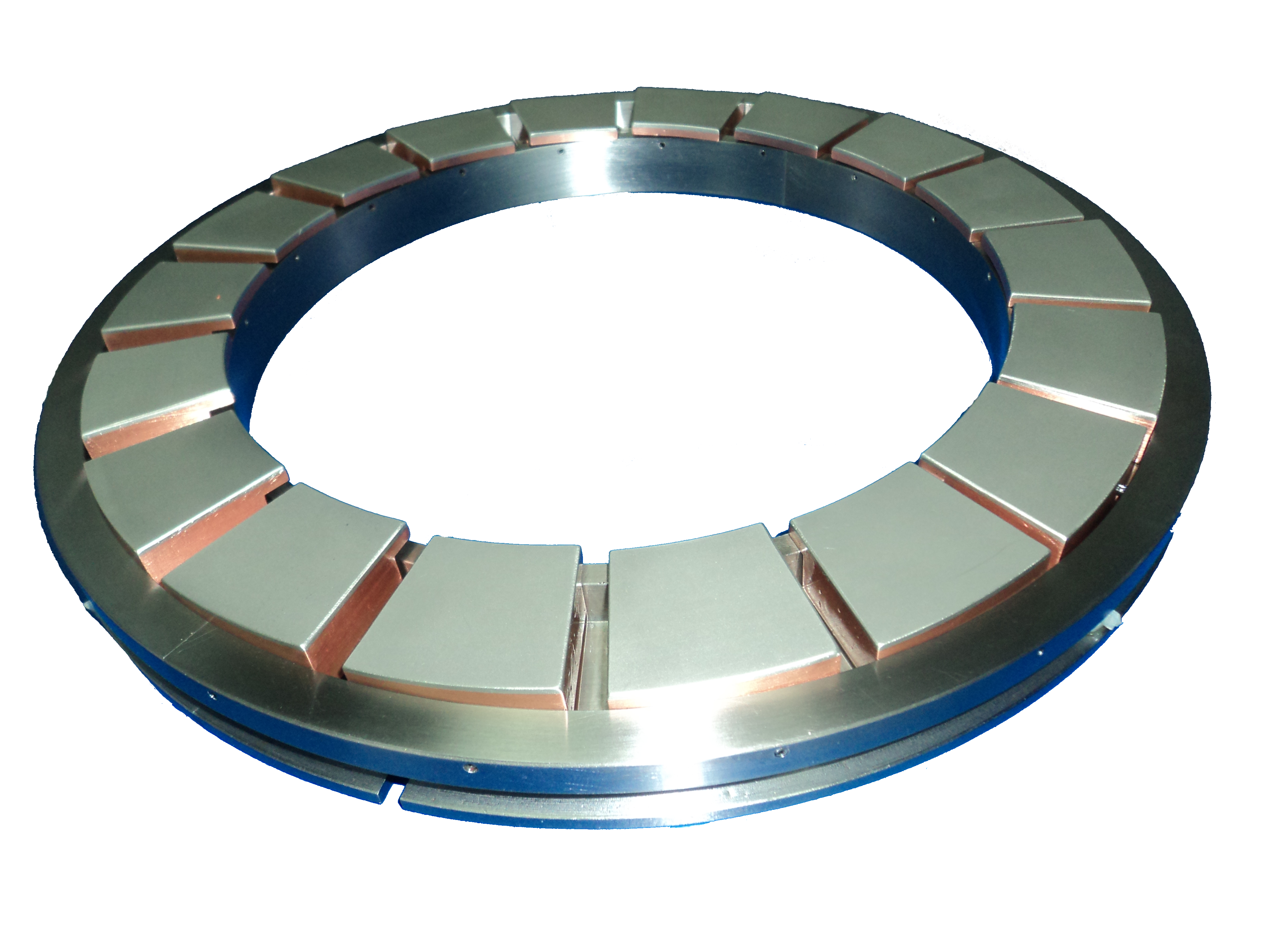

Thrust Bearing Assembly

Turbine Loaded Thrust Bearings

REPAIRED COMPONENTS

Lube Oil Pump Bearings

Unloaded Thrust Bearings for Turbines

Tilting Pad Journal Bearings

Insulated Motor Bearings

Gear Box Bearings – 4 Lobe

Vertical Bearing Thrust Pads

REVERSE ENGINEERING

For Manufacture & Repair

SHAHEEN is able to re-engineer replacements for small and large components. These parts can be manufactured or repaired as an exact duplicate or even modified for improved performance characteristics based on client requirements.

QUALITY CONTROL

Quality is never an accident; it is always the result of high intention, sincere effort, intelligent direction, and skillful execution; it represents the wise choice of many alternatives.” – William A.

Quality Assurance and Quality Control Procedures

ISO 9001:2015

- Incoming Job Inspection

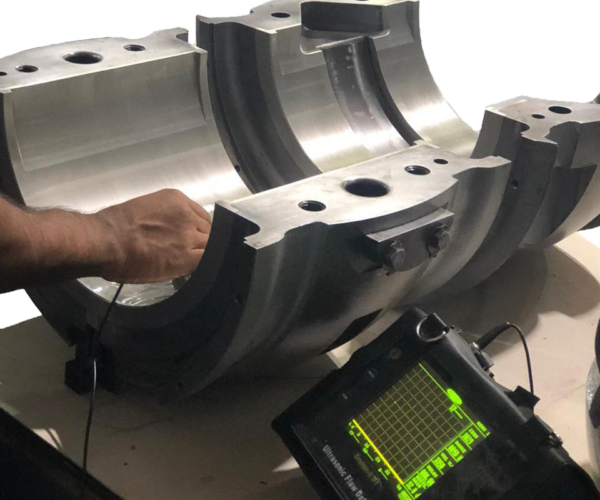

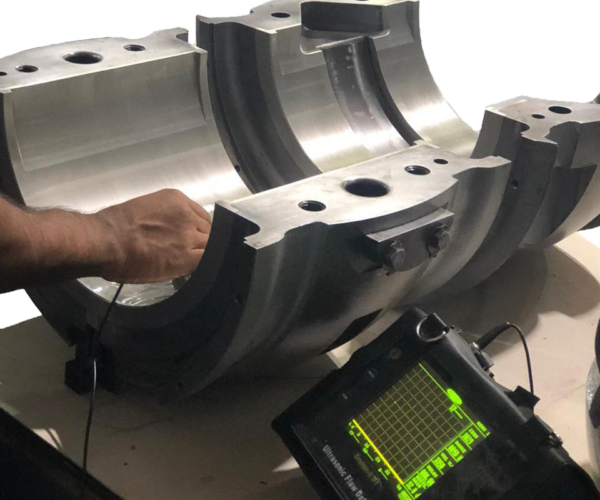

- Surface Finish Testing Ultrasonic Inspection

- Non-destructive testing (NDT)

- Final Progress/Dispatch Testing/Delivery

GOODS INWARD INSPECTION

On receiving the components, a comprehensive dimensional and visual check of their original state is made.

An initial inspection report will then be forwarded outlining these facts and whether a good repair is feasible.

COMPONENT INSPECTION

All manufactured or repaired components undergo visual, dimensional, ultrasonic and where requested dye penetrant inspections. Dimensions are checked to ensure that every critical one is within tolerance given by the drawings.

FINAL INSPECTION

Every white metal lined component is ultrasonically tested by our inspection department and issued with a certificate of bonding. All manufactured and repaired components are dimensionally inspected and certified.

PACKAGING FOR TRANSPORTATION & STORAGE

Every job is packed to ensure:

-safe transportation anywhere in the world,

-easy identification using the customer’s reference number,

-placement into depot or site storage with no further preparation, and

-extreme resistance from degradation caused by external elements.